How I took apart and repaired my notebook LCD

screen with water damage

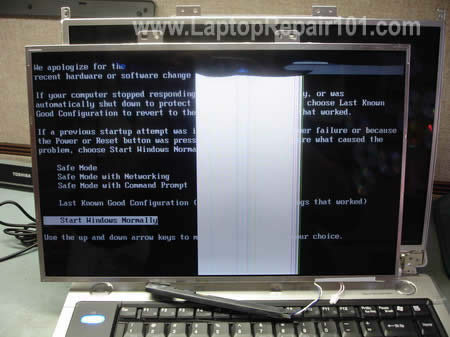

Yesterday took apart and repaired my notebook LCD screen with water damage. The screen itself was working just fine but it had two different problems.

- previous owner spilled water on the laptop. Somehow the water got inside the LCD screen and left stains inside the screen. The water marks were very noticeable on a white background and it was very irritating.

- the screen also had dust and lint inside also very noticeable on a white background. I have no idea how it got in there but I decided to clean it up too.

To fix both problems I had to open up the LCD screen. This was my first experience on opening a notebook screen. I was pretty confident because I didn’t really care if I break the screen, I just wanted to know if it’s possible to fix it.

Warning: the LCD screen can be easily damaged if you open it up. If you do something wrong the screen might become completely unusable and you’ll have to buy a new screen. It’s very expensive. Think twice before you decide opening the screen. Continue at your own risk.

Here’s my Dell Latitude D610 notebook with water damaged screen I’m going to take apart.

First of all remove the battery from the notebook.

First of all remove the battery from the notebook.

Lift up rubber screw seals and remove all screws.

Carefully separate the screen bezel from the LCD cover and remove the bezel.

Remove two screws from the front and two screws from both sides.

Carefully remove the LCD screen from the cover and place it on the notebook base. Disconnect the video cable and the inverter board cable.

On this model the inverter board is attached to the screen with two screws. Remove both screws, disconnect the screen cable and remove the inverter board.

Carefully peel off sticky tape and foil and put it aside. You’ll have to put it back in place during the screen reassembly.

Remove two screws from both sides of the screen.

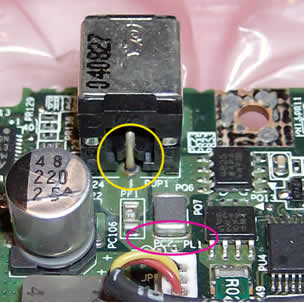

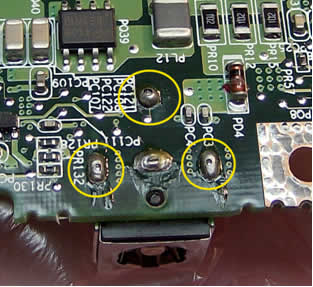

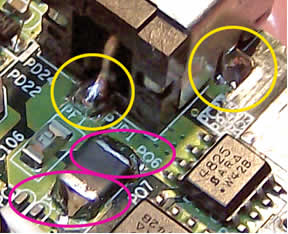

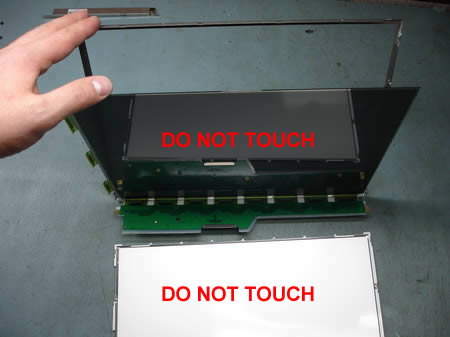

Carefully place the screen upside down on a flat surface. Carefully unglue the film that covers the circuit board and remove two screws from the board (top circles). I wasn’t really sure if I have to remove screws on the bottom, so I removed them just in case. Do not touch the circuit board with fingers.

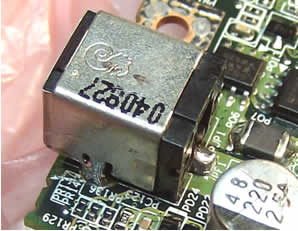

After both screws are removed you should be able to lift up the circuit board. Be careful, it’s still attached to the LCD.

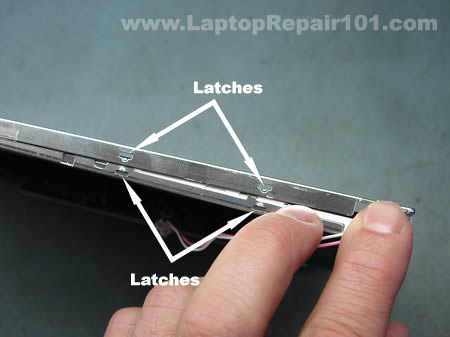

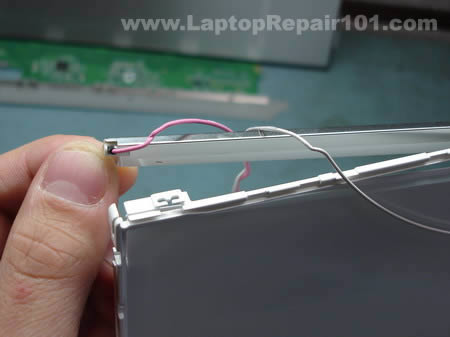

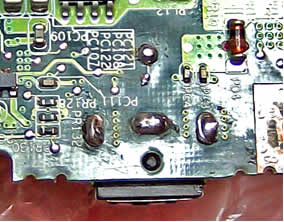

Start unsnapping the metal frame from the screen. There are a lot of latches on all sides of the screen. You can unlock them with nails or a small flat head screwdriver.

After all latches are opened you should be able to separate the screen into three pieces: metal frame, LCD and background (not sure about correct technical name).

If you have lint or dust inside the screen, probably you’ll find it between the LCD and the background. Do not touch LCD or background with your fingers. I was able to remove dust and lint up with a very soft cloth, barely touching the LCD and background surfaces.

After I split the screen I found that the background has a few some kind of optical layers (three transparent sheets) and in my case they were damaged by water. The water dried out and left stains between these optical layers.

In my case removing dust and lint wasn’t enough and I had to go further.

If you have lint or dust inside the screen, probably you’ll find it between the LCD and the background. Do not touch LCD or background with your fingers. I was able to remove dust and lint up with a very soft cloth, barely touching the LCD and background surfaces.

After I split the screen I found that the background has a few some kind of optical layers (three transparent sheets) and in my case they were damaged by water. The water dried out and left stains between these optical layers.

In my case removing dust and lint wasn’t enough and I had to go further.

Very carefully separate the LCD with attached circuit board from the background.

To remove damaged optical layers it’s necessary to remove metal locks on both sides of the screen. It’s like a small clip that keeps layers in place.

After I removed both clips, I was able to look between the layers. At first I tried to clean up the dried water marks with a soft cloth but it didn’t help. The stains were still visible and didn’t want to go away.

Fortunately I had another similar screen laying around, it had a cracked LCD. I decided to borrow the optical layers from the cracked screen and transfer them to my screen. I wasn’t sure if it’s going to work, but as I mentioned before I didn’t really care if I break the screen. It was just an experiment.

So I disassembled the cracked screen and carefully transferred the white background and all transparent layers to my screen.

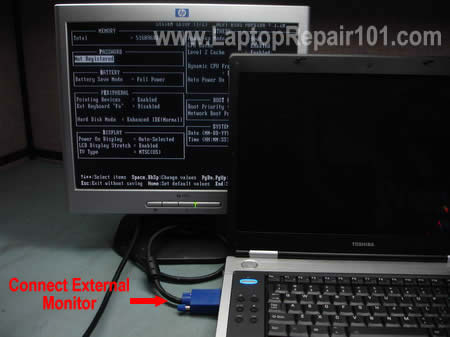

After that I assembled my screen back removing dust and lint with a very soft cloth. Breathlessly connected my new screen to the notebook. Turned it on and…

That’s a miracle, it works!

No dust, no lint, no water mars inside the screen! It’s clear and the background is absolutely clean!

Fortunately I had another similar screen laying around, it had a cracked LCD. I decided to borrow the optical layers from the cracked screen and transfer them to my screen. I wasn’t sure if it’s going to work, but as I mentioned before I didn’t really care if I break the screen. It was just an experiment.

So I disassembled the cracked screen and carefully transferred the white background and all transparent layers to my screen.

After that I assembled my screen back removing dust and lint with a very soft cloth. Breathlessly connected my new screen to the notebook. Turned it on and…

That’s a miracle, it works!

No dust, no lint, no water mars inside the screen! It’s clear and the background is absolutely clean!

My donor screen had a cracked LCD but it had a good working backlight tube. The backlght tube is very fragile and it’s located inside a metal casing. I didn’t remove the backlight tube, I just broke off the entire metal casing from the plastic frame. I’m going to use this backlight tube for testing purposes.

If you fixing a Dell laptop yourself, probably you’ll need a service manual. Some Dell service manuals provide step-by-step laptop disassembly instructions.

Are you looking for a new screen? You can find very inexpensive brand new LCD screens just search for your laptop model.